BRB System

This Buckling-Restrained Brace (BRB) System is a seismic technique that is intended to protect buildings from Earth Quakes and Bomb Blasts. The purpose of BRB is to avoid buckling of the supporting brace during a Seismic occurrence. The high quality design is fabricated to deliver an easy to produce and cost effective solution for any seismic activity.

Application

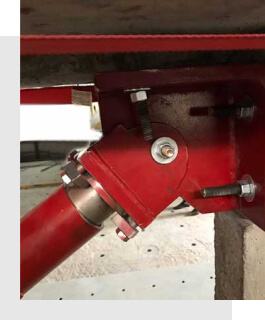

A fully Buckling-Restrained brace system that can be assembled on-site for seismic reinforcement. Made from special Alloy AISI Grade steel, the BRB System is the most cost effective technology. The beauty of the system is that it can be retrofitted and installed into existing buildings as well as new construction.

- Eliminates failure from buckling of the brace under compression, forcing the failure if any, to take place, as desired, from elongation of the core.

- Assembles quickly reducing costs as well as measurement errors and installation time on the jobsite.

- Low cost assembly allows for the use of higher ductility core materials, improving the energy absorption and therefore performance of the system.

- Applies itself to new construction or seismic retrofits of both concrete and steel structures,broadening the potential customer base.

The yielding core steel bar is fully restrained against buckling over its entire length eliminating any unsupported segments of the core and, therefore, controlling buckling. The system is 100% Canadian origin and Patented and can be supplied in CKD form for “on site” assembly and installation.

With these significant cost savings, more ductile special steel is used as a yielding core to provide much greater energy absorption and significantly improve the performance of the brace.In the unfortunate event of Earth Quake or Bomb Blasts only the inner core of BRB System need to be replaced. Steel Canada Limited is the exclusive Licensee and manufacturer of BRB System at its Mississauga, Ontario, facility.