Our Products

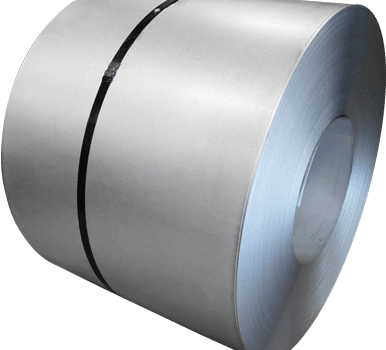

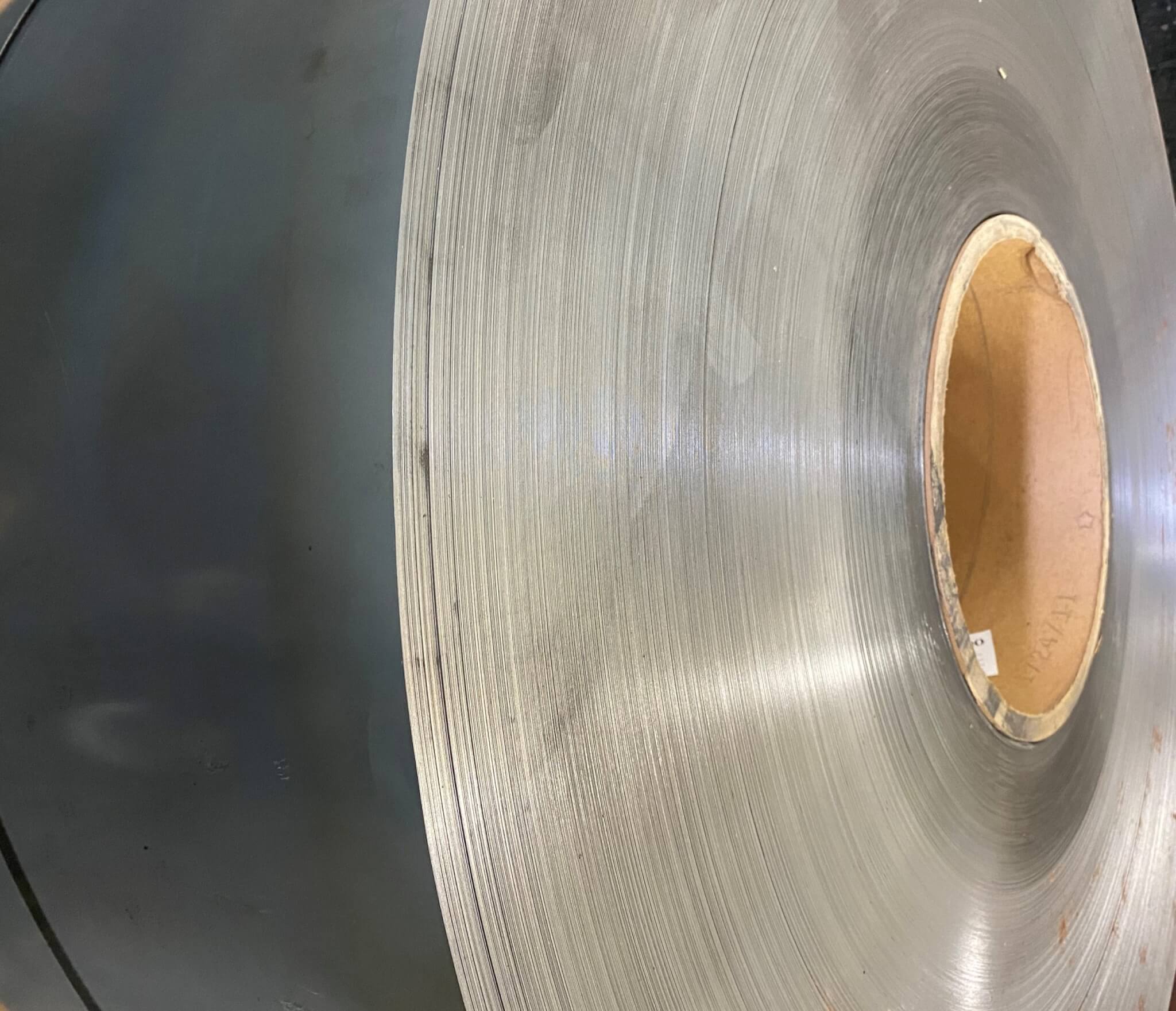

Cold Rolled coils are cold reduced from HR Pickled Steel. The steel is cold reduced to the desired thickness and annealed to a specific grade.

A Hot Rolled Coil is the most basic type of flat-rolled steel. It can be utilized in its original form or serve as base metal for Cold Rolled and Coated Steel products.

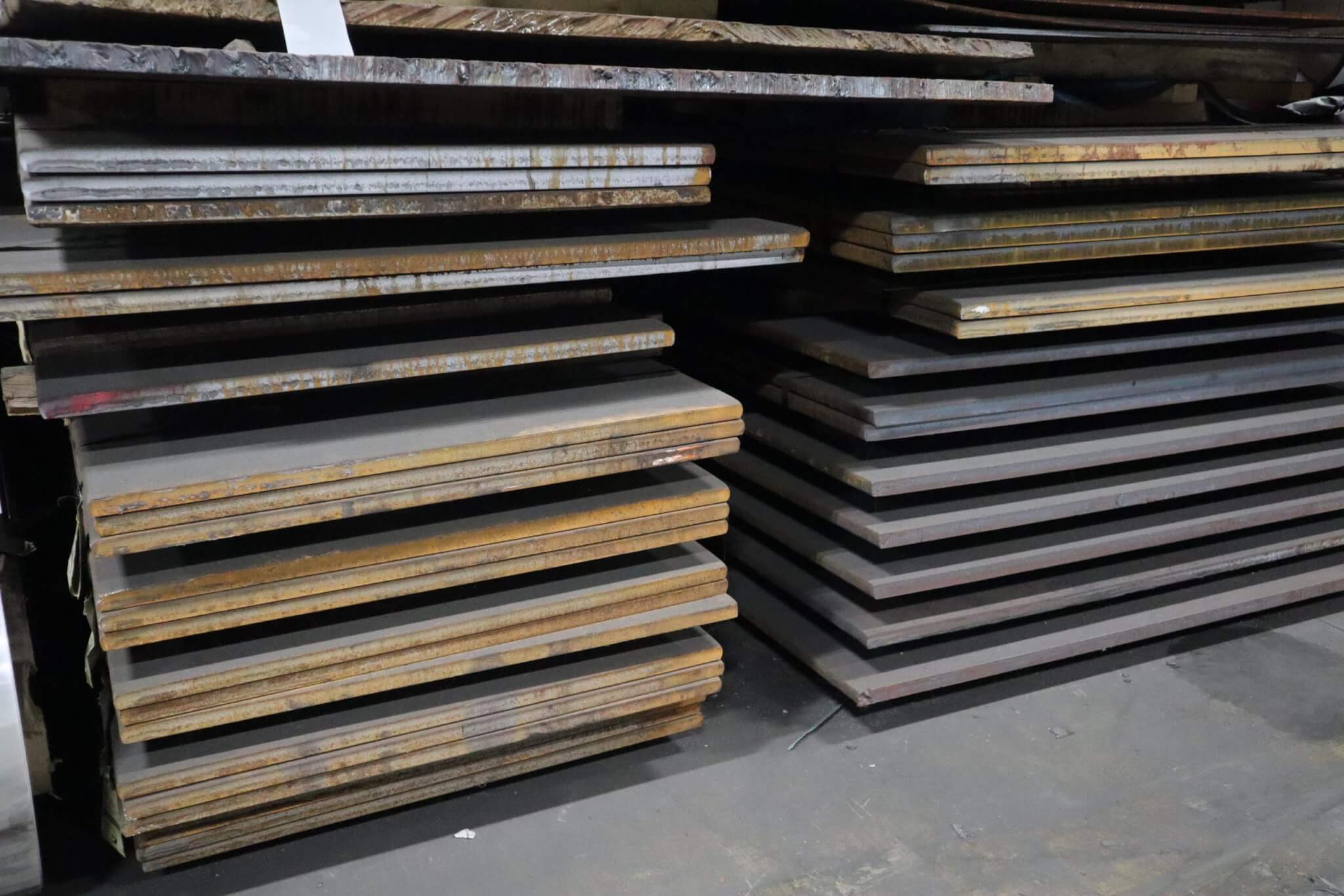

Hot Rolled Plates – Excess Prime & Secondary

A Hot Rolled Sheet is the most basic type of flat-rolled steel. It can be utilized in its original form or serve as base metal for Cold Rolled and Coated Steel products.

The pickling process removes scale and rust from Hot Rolled Steel. HR P&O products have a smoother finish and is promptly oiled to prevent rust.

Galvalume Coils combine elements of aluminum and zinc in the coating process. This process provides the best protection against rust and corrosion.

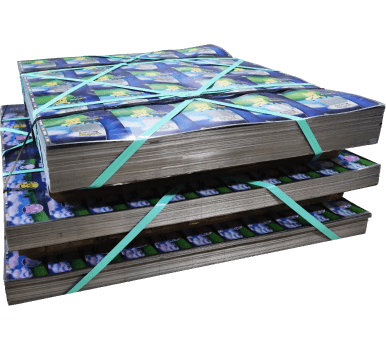

Pre-painted steel is a continuous process of applying primer and paint to steel in a coating line.

Galvanized Coils are made from a base of Cold Rolled or HR P&O Steel. The Steel passes through a zinc coating process that prevents the steel from rust.

Galvannealed Coils are a type galvanized steel that has similar rust prevention properties with a harder coating that prevents the steel from scratching.

Tin Free Steel (TFS) Coils are produced from Black Plate products that run through a metallic chrome coating process.

Electrolytic Tin Plate (ETP) Coils are produced from Black Plate products that run through a tin coating process.

Black Plate is essentially a cold reduced product with a very light thickness. It is primarily used as the base to produce other Tin Mill Products.

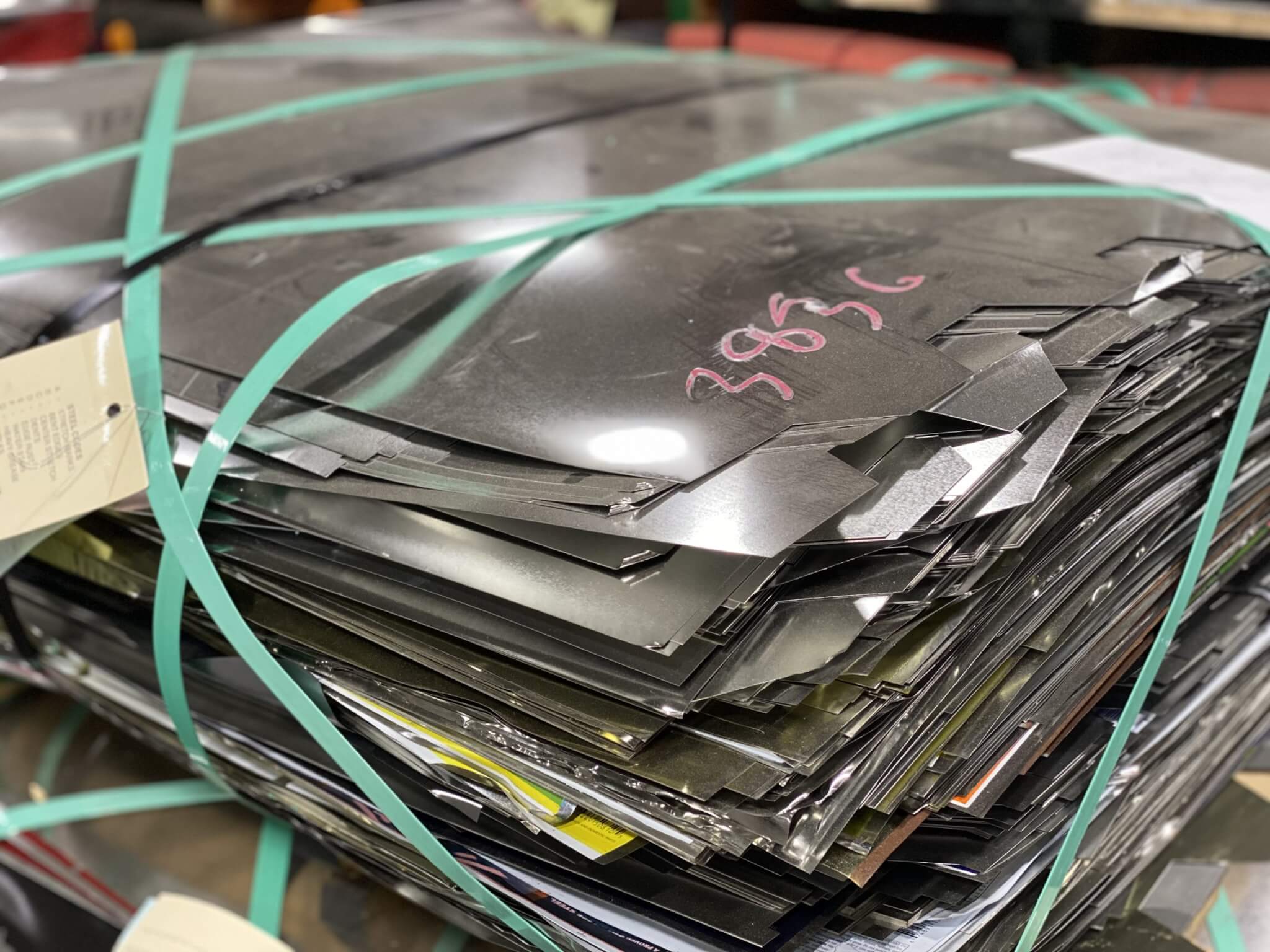

Heavy Melting Scrap includes used steel and wrought iron pieces, which are then categorized into two grades, HMS1 and HMS2.